The Jones Brother factory was specifically designed to build boats. The structure was completed in 2001 and was fully operational in mid-2002. The two main buildings total 50,000 sq. ft. with plenty of room for future expansion.

Climate Controlled Environment – Buried in the cement floor is a five-mile network of water pipes used to heat the building and maintain the resins, gel coats and molds at a constant temperature. We are able to heat over an acre of enclosed manufacturing facility with only 400,000 BTUs – less than the average home. This climate control system simplifies the manufacturing process by maintaining a very controlled environment for the materials used in boat construction, and allows us to consistently deliver the best boat possible. Most boat manufacturers have a difficult time making seasonal adjustments with lamination schedules caused by large temperature variations. Our plant maintains “laboratory” conditions every day.

Powered by Air – A great deal of effort went into designing the air system that supplies most of the tools at the factory. Wherever possible, air tools are used during manufacturing. They last far longer, are much safer and more efficient than electric tools. We use “rotary screw” compressors which are extremely efficient and durable. They’ve been running almost non-stop since the plant opened.

A lot of thought also went into our electrical power systems. For efficiency, like most factories, the electrical equipment runs on three phase power. However, due to the reliance on the air systems and efficient use of our power systems, we are able to run the entire factory on less than 480 amps service. When the local power company ran an assessment of the plant, they found it was the most efficient operation they had ever seen.

Eco-Friendly – The manufacturing plant is extremely ecologically and environmentally friendly. The air filtration system works so well that employees are not required to wear respirators during lamination. The resins and gel coats used in construction produce the lowest emissions possible with current technology. Even the flotation foam produces zero harmful emissions. These materials and compounds are expensive, but they do the least harm to the environment and help provide a safe workplace for our employees.

Our company also believes in eliminating as much waste as possible during construction – we don’t like adding to landfills or generating unnecessary waste. The molds were designed to reduce the trimming and keep waste to an absolute minimum, which reduces the manufacturing costs for our company.

The creeks and salt marshes behind the manufacturing plant produce some of the best shellfish and shrimp in the area, and most of the employees at the plant are connoisseurs of good seafood (Southern style). There is a great deal of self-interest in keeping the local environment healthy and bountiful.

Molds – Success for a boat company is heavily dependent on the quality of the molds used in construction, and the care and precision that went into their creation. At Jones Brothers, all of the fiberglass molds were conceptualized, designed and hand built in our factory. We spent a great deal of time and effort to create perfect molds, which can consistently produce quality parts time after time. Great molds, and the talented people that use them, help create the boats that live up to our high expectations.

Woodshop – The name “Woodshop” is a holdover from the good old days – no wood is used on any of the boats currently manufactured by Jones Brothers. Nowadays, the woodshop cuts the foam and other composite pieces that will be used by Lamination and Small Parts.

Lamination – Lamination builds the hull, stringers, and floor. These major components of the boat are assembled in Lamination, and then the hull is passed to Finishing for final assembly.

Small Parts – The Small Parts group builds the console, deck cap, hatches, and any necessary livewell, jump seats, and/or leaning posts for a boat. Most of the fiberglass parts used by Jones Brothers are built in-house to insure the quality and consistency of the finished product.

Finishing – Early in the manufacturing process, the Finishing department examines the sale order for the engine(s) and options selected by the customer. Inventory is set aside for the boat for final assembly.

When Finishing gets the hull from Lamination, and the remaining components from Small Parts, each piece gets a thorough inspection and any imperfections are fixed. Once all the parts have the proper fit and finish, the boat continues down the assembly line and finally comes together.

Cutting fiberglass material on the cutting table – Lamination cuts patterns from rolls of fiberglass material. Using patterns insures consistent weight and strength when they are interlocked during the construction process.

Woodshop cuts the foam and composite pieces used in the boat – While Lamination is cutting material, the woodshop cuts the foam and other composite pieces that will be used by Lamination and Small Parts.

Applying the gel coat into a mold – After prepping the molds, the gel coat is applied to the hull mold.

Hand laying fiberglass into the hull mold – After the gel coat sets, the fiberglass patterns are handlaid, and all air bubbles are “picked” from the fiberglass and resin layers for strength and longevity. Also, the lamination layers are applied using a “schedule” to insure consistent thickness and weight.

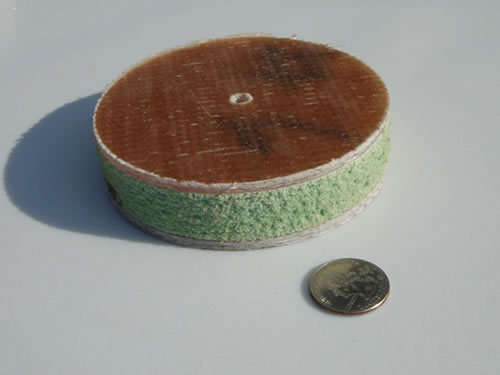

Installing the transom – The transom is now constructed using a special high-density foam core. The process insures a perfect bond between the hull lamination layer and the new transom.

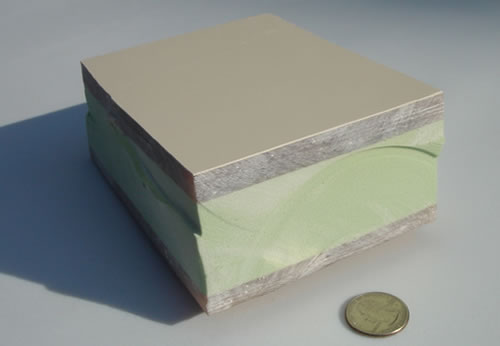

A cross section of the Transom – The transom uses a foam core with special properties. It’s very heavy, dense, extremely difficult to compress and is absolutely waterproof. The finished transom has approximately 1/2 an inch of laminate on each side of the foam core.

Building the stringer grid – The lamination crew builds the fiberglass stringer grid at the same time as the hull. The fiberglass patterns used on the stringer grid are interlocked during the build process for maximum strength. Sheets of recycled ABS plastic are strategically placed inside the stringer grid. The ABS composite material holds screws extremely well and will be used to anchor the console, and optional seats or leaning post live wells.

Pulling the stringer grid from the mold – There is a LOT of glass used in the stringer grid. Hoists are being used to pull the stringer from the mold.

Adding glue to the stringer grid – The stringer grid is now finished, and the crew is adding the glue to the bottom of the grid.

Glassing in the stringer grid – After the stringer grid has set, additional glass is added to insure a solid bond with the hull.

Hull with stringer grid tank and foam installed – The tank has now been installed and foamed in-place. Foam also gets injected inside the grid and into the cavities under the floor. The black parts are ABS composite sheets built into the stringer grid which are used to anchor the console, and optional seats or leaning post live wells.

Building the floor on the vacuum table – The Lamination crew also creates a composite floor on a vacuum table.

A cross section of the floor – The foam core used by the floor looks somewhat like the foam “noodles” used by kids at a swimming pool – it’s extremely light, thin and flexible. The foam sheets have very small holes that penetrate the material. When vacuum bagged, resin fills the holes to create support columns inside the foam. When finished, the floor is extremely stiff and strong, and able to withstand the impact of a dropped anchor.

Apply glue for the floor – After installing the fuel tank and filling the floor cavities with foam, the floor is glued on top of the stringer grid.

Install the floor – Note the lack of deflection in the floor being installed in this photo. The flexible foam core with the lamination installed is now a very solid structure that can easily support a full-size adult standing in the middle of a suspended floor. Once installed on top of the stringer grid, the floor is super solid.

Gluing and glassing the floor to the hull – After the floor has been glued to the stringer grid, the floor is also glued and glassed to the hull.

Painting the cockpit – The cockpit has been ground and sanded smooth, and is now being painted. The non-skid surface is applied during this last step in Lamination.

The painted hull ready to come out of lamination – Lamination is now finished with the the basic hull, and it’s ready to move to Finishing.

A console and deck cap being built by Small Parts – While Lamination has been constructing the basic boat, Small Parts builds the console, deck cap and other options used to finish the boat. Note the foam core used in the deck cap mold on the right. The core creates parts that are very strong and rigid.

The deck cap being installed – The boat is finally coming together. After installing the deck cap, the finishing crew will add the console, leaning post and hatches.

Adding the rub rail – Hardcrab, one of the finishing crew, installs the rub rail on the Cape Fisherman.

Assembling the console – Randy gets started assembling the console for the new boat. The console is the nerve center for all Jones Brothers boats. The wiring, switches, cables, and batteries are easily accessible.

Buffing the Hull – The hull and all the components built by Small Parts are inspected. Any imperfections are repaired, and all the surfaces are polished.

Installing the Console – The console is up on-end, and adhesive is being added to the bottom. After carefully aligning the console, it will be flipped down and anchored into the ABS composite that was built into the stringer grid.

Installing the Engine – A hoist is being used to install the Yamaha four-stroke on the transom.

Adding the Decal – Donnie adds the Jones Brothers decal. The crew also details the boat, and goes through a checklist to insure that all components are installed, and the cushions, plugs, accessories are on-board before shipping.

Almost out the door – The boat is ready to leave the factory, and will soon be loaded onto a truck for transport to a dealership.